Easyflow holds approved quality management systems (ISO 9001 : 2015) applying to the design of underfloor heating and the supply and installation of insulation, underfloor heating and liquid screeds.

Our installers installed a 1200 gauge damp proof membrane before insulating with a combination of 75mm and 25mm insulation boards due to an uneven existing concrete sub-base.

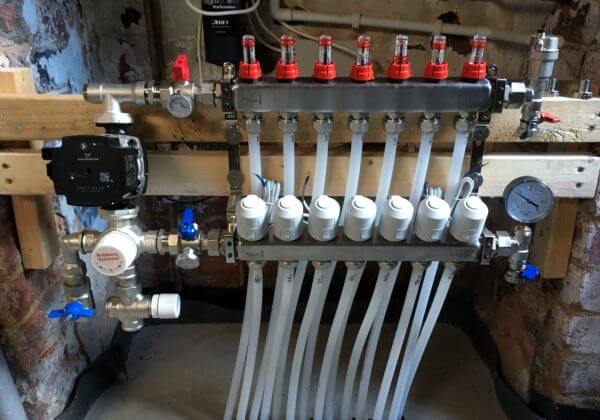

A central location was chosen by the client for our installers to locate the manifold before installing flexible PEX piping in accordance with a bespoke design.

Installers took a laser level survey of the floor in order to accurately calculate the quantity of screed required to meet set datums.

The Easyflow team then supplied, pumped and laid the screed as required.

Where To Find Us